200D Product Refinements

![]()

Several product refinements will be made to the Meyers200D. Some refinements are changes that conceivably would have been made already had the aircraft been in continuous production since 1967. The engine and propeller are current production models that derive directly from the originally certified Continental IO-520A so they can be added easily. Some accessories have been updated but by far the greatest advances have been in the electrical and avionics areas.

The other area that needs attention is passenger comfort. Air conditioning and increased ventilation will be provided. The changes are described in detail in the pages that follow.

A careful analysis of the competition and a thorough knowledge of the wants of the target general aviation market have led to the establishment of the following refinements which will form the bulk of the R&D program to be undertaken by Meyers Aircraft Company:

![]()

1. A gross weight increase from 3000 to 3300 pounds.

2. An engine change from the Continental IO-520 to the Continental IO-550

3. Change the two-blade propeller to a three-blade propeller.

4. Redesign the nose bowl cowling for decreased drag and a better appearance.

5. Install a piano hinge or other access along the top of the engine cowling for easier pre-flight.

8. Modify the fuel gauges and selector valve.

9. Increase the fuel capacity from 80 to 100 gallons or more.

15. Incorporate several already approved minor changes such as the Cleveland Brake installation, aerodynamic wing tips, and other minor maintenance items i.e. improved landing gear bushings and new style fuel lines.

17. Engineer and install a state-of-the-art avionics package.

![]()

Management has determined that 3300 pounds would be the maximum attainable without requiring extensive re-testing of the major airframe components. Certain components have been tested to a maximum gross weight of 4000 pounds in the Interceptor 400, notably the center section and main landing gear. These components were unchanged from the Meyers 200D to the Interceptor 400 so this testing does apply. Most of the critical wing, engine mount, landing gear and flight controls have been tested to 110% of ultimate at 3000 pounds. But the tail and empennage had only been tested to 100%. For these reasons, it has been determined that the most effective gross weight increase would be to 110% of 3000 pounds or 3300 pounds.

At 3300 pounds and 80 gallons of fuel, there is room for full fuel, four people and 100 pounds of baggage. By offering 100 gallons of fuel as discussed below, one could have full fuel, three FAA standard people and 102 pounds of baggage. (100 gallons times six pounds to the gallon, plus four people at 170 pounds, plus 102 pounds equals the 1212 pound useful load.) This is very acceptable for an aircraft of this type as most engineers feel that if you can carry full fuel and fill the seats, the aircraft is not designed properly and you have given up some performance. In fact, at a gross weight of 3300 pounds, the Meyers 200D will have a useful load of 100 pounds more than the Bonanza, which is a prime target competitor.

![]()

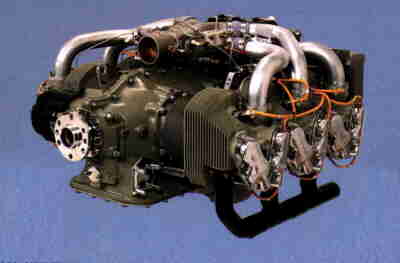

The engine in the Meyers 200D has been the Continental IO-520A, a horizontally opposed, six cylinder, normally-aspirated, fuel injected engine producing 285 maximum continuous horsepower at 2700 rpm. This series engine is still a current production model and is still used in the Bonanza, Mooney Ovation, Lancair and others. It powered the Cessna 210's and has been used in many twin-engine planes (most of the Cessna twins).

| About ten years ago, Continental introduced an updated version of the IO-520, called the IO-550 and is recently working on a FADEC (full authority digital engine control) system for this engine. The IO-550 is the same engine as the IO-520 with a 5.25" bore but the stroke is increased from 4.00" to 4.25" to get more cubic inches. The IO-550 is rated at 300 continuous horsepower at 2700 rpm. |  |

Continental IO-550 engine |

The Meyers 200D can limit take-off rpm to about 2650 and still get 285 horsepower. This reduces noise and also allows for a more reliable engine. Initial field service reports verify this. The FADEC system will reduce the pilot's work load by automatically leaning the mixture and controlling the spark advance with an increase in altitude or other operating conditions.

But the most significant improvement is perhaps the real horsepower available. Officially both engines are rated at 285 horsepower. However, unofficially, Continental technical representatives have stated that the IO-520 was rated at 285 horsepower without accessories and the IO-550 is rated at 285 with full accessories. If the latter rating is accurate, this may translate into almost 40 horsepower more available at the propeller. Some other tests tend to verify this. Several STC's have been granted for the Bonanza and the Cessna 210 to use the IO-550. Field reports confirm that speed increases of eight to ten knots occur simply by replacing the IO-520 with the IO-550.

Since one of the primary goals of this program is to equip the Meyers 200D to cruise at or above 200 knots, the change from the IO-520 to the IO-550 is very important. Also from the standpoint of certification with the FAA, the change is considered minor and will not necessitate a lot of testing as the engine just bolts onto the existing mounts and the same horsepower will be used for takeoff. However, more horsepower will be available at cruise. The engine can, additionally, be run at 300 horsepower which gives some cushion should extra horsepower be needed due to the above gross weight increase for take-off and climb performance.

Recently, Meyers Aircraft has assisted two Meyers 200 series owners in California, to install the Continental IO-550 engine in their aircraft. This installation was considered so minor by the FAA, they allow the installations to be approved on an FAA Form 337. They did not have to be STC’d. These two aircraft are original and have had no drag reduction program applied. Reliable reports from the owners and a test pilot show that the aircraft delivered 194 and 198 knots of speed. This clearly indicates that the goal of over 200 knots cruise speed can be attained.

![]()

Talks are ongoing with Hartzell and McCauley concerning their scimitar shaped three blade propellers. The advantages of using this propeller over the two-blade currently certified will be more modern looks, lower take-off noise, better climb performance and, with the scimitar shaped blades, it may be possible to get cruise performance equal to the two-blade. In any event, the propeller is one the most noticed parts of the airplane and it will add a special appearance to the Meyers 200D.

![]()

Along with the new propeller, redesigned cooling inlets will perhaps do the most to modernize the appearance of the Meyers 200D. While they are being redesigned for aesthetics, they will also be redesigned to lower the cooling drag. This is possibly the greatest area of drag reduction and is expected to offer a real possibility for speed increases - maybe even more than the engine change. Along with the inlet redesign, the cowl flaps will be changed and possibly the engine baffling system. Engine induction air inlet changes need to be made to reduce the pressure drop as much as possible. The current system with the hated Brackett air filter probably robs two inches of mp at the least. Engineers are very optimistic about the possible gains to be made in these areas. Also the cowling needs to be redesigned to allow easier access for replacement of the taxi light or the lights need to be relocated.

![]()

One of the greatest areas of vexation is the difficulty to properly pre-flight the Meyers 200D's engine compartment due to the way the engine cowling attaches. One has to remove several screws and unfasten many camlock fasteners. Even then, the cowling comes off in one big piece which is almost impossible for one person to handle. The cowling needs to be hinged along the top so it can be propped open on each side for access to the engine compartment, like the Bonanza. This is also an important safety factor as most pilots will not do a thorough pre-flight of the engine if it is too difficult to get into the engine compartment.

![]()

The Meyers 200D does not have any rudder trim. As with any high horsepower single, it requires a lot of right rudder on take-off and throughout the climb to stay in coordinated flight. Many pilots have stated they feel a rudder trim would be a great enhancement. The electric variety, with a small servo motor mounted in the tail, is the easiest to install and the least expensive, as opposed to running cables and/or pulleys for a mechanical system.

![]()

To achieve the target of 200 knots cruise speed, a general drag reduction, in addition to the engine, prop and cooling drag reduction, may be necessary. This is perhaps the least significant but it is also the easiest to do, and involves a lot of common sense changes as well as incorporating several drag reducing ideas tried and proven by the Meyers Owners Association. Some of these common sense refinements include:

1. Removing the exposed rotating beacons.

2. Putting on low drag style wing tips.

3. Aerodynamically improving the towel bar assist handle.

4. Making sure the gear doors are rigged properly.

5. Flush-mounting the window glass.

6. Using low drag radio antennas.

7. Sealing the flap gaps and the elevator and rudder gaps.

8. Installing wing root fairings.

To see a couple of initial tuft tests, Click Here.

![]()

The present fuel system consists of a five position selector valve located on the pilot's side panel and a single fuel gauge located in the same spot. There are four tanks in the Meyers 200D, each tank holding 20 gallons. Two problems are immediately evident:

1. The gauge only shows the quantity of fuel in the selected tank. Therefore, if one forgets which tanks have been emptied, one must select and operate for a short time on the empty tank to read its fuel level. This offers the possibility of the pilot switching to an empty tank at a very inopportune moment, possibly shutting down the engine due to fuel starvation.

2. In the unlikely event of incapacitation of the pilot, the copilot has a very hard time, if not impossible, in reaching the fuel selector and seeing how much fuel is left in the tanks.

The solution chosen is to move the selector valve to the floor area between the pilot and copilot seats and to put four fuel quantity indicators in the panel where both can see them. The gauges will display the quantity in their respective tanks at all times. It is planned to install a green indicator lamp in or directly above each gauge which will be controlled by the position of the selector so that it will light up to indicate the tank actually selected at that time. With the recent advances in digital instrumentation, it may also be feasible to have an amber light in or above each gauge also, which would illuminate when the respective gauge drops below a certain level of fuel.

![]()

The present fuel capacity of 80 gallons is adequate and about standard (the Bonanza is also 80 gallons) for this type of aircraft. However, more range is always desirable and, in some instances, can even be an added safety factor. The first production AeroCommander 200D (SN301) was delivered with factory standard 100 gallon tanks . This was done by making the inboard wing-root tanks wet, increasing their capacity to 30 gallons each, resulting in two tanks with 20 gallons each and two with 30 gallons each.

The 3000 pound gross weight of the Meyers 200D, however, made this extra fuel almost impossible to legally carry, so subsequent aircraft were reduced to four 20-gallon tanks. With the new gross weight of 3300 pounds, the extra fuel would be put to good use. Since the engineering and paperwork exist for SN 301, it will be simple to incorporate and will give the Meyers 200D the greatest range of any of its competitors.

There also exists an STC for tip tanks that provide an end plane effest as well as an increase in fuel quantity. Properly engineered, it is possible to not have to subtract the fuel carried in the tip tanks from the useful load as this weight actually unloads the wing, unlike fuel carried inboard.

Another method of both increasing the fuel capacity and simplifying the fuel selector system is to simply install the already certified wings of the Interceptor 400 on the Meyers 200D. This would reduce the tank number from four to two and give 145 gallons of fuel. There would now be a simple left, right, both, off selector valve with two gauges. This possibility will be explored at the appropriate time in the program.

![]()

The Meyers 200D production was discontinued in 1967. Since that time, there has been a tremendous revolution in autopilots. Today, panel mount digital autopilots that can be expanded to include a yaw damper and a full flight director are commonplace.

Century Flight Systems did certify a first generation modern autopilot, consisting of the Century I, II, III and IV series, in the early 1970's. Paul Whetstone, through Whetstone Aire, has personally installed several of these systems and the Interceptor 400 has a Century IV system including yaw damper, HSI and Flight Director, installed and flying well. A major drawback to the Century autopilots is their dependence on attitude information from a vacuum driven attitude indicator. Thus, when (not if!) the vacuum pump fails, you lose the gyros as well as the autopilot. And the NSD-360 HSI offered by Century is, in the experience of management, the worst HSI ever offered due to its miserable maintenance record.

The Meyers 200D will have as standard equipment a full two axis (pitch and roll) autopilot. It is believed that a fully functioning autopilot is the single greatest help in reducing pilot workload and will help avoid mishaps. The FAA will not allow single pilot Air Taxi (Part 135) operations without a functioning autopilot.

Management is currently in negotiations with several autopilot manufacturers to determine the best course of action and performance for the aircraft. As of this writing, it is believed an S-Tec series autopilot will be offered as standard due to the redundancy afforded. The S-Tec does not depend on vacuum driven gyros for its inputs, thus when the vacuum pump fails, the autopilot will still work and could be a real life saver, literally.

![]()

In the very recent past, there was not much concern for noise levels in the cockpit. As the World War II pilots aged and their hearing loss deepened, major studies were commissioned which linked cockpit noise to hearing loss. Now we understand that cockpit noise contributes greatly to fatigue as well, and can even be a major safety concern for the short term. Modern manufacturers are paying much more attention to sound deadening and are becoming very sophisticated in their use of instrumentation to analyze the different types of sound and come up with different materials to quiet aircraft.

![]()

Meyers 200D Standard Sound Proofing

As standard, the Meyers 200D will have heavy 1/4" thick Plexiglas (it originally had 1/8" Plexiglas) and foam sound deadening insulation. An inflatable door seal will eliminate wind noise around the door. These, together with the new engine and three-blade propeller, will make the Meyers 200D factory standard aircraft as quiet or quieter than its competition.

Anthony Bongiovi, of Power Station Studios, New York has been chosen to consult on special soundproofing and optional stereo systems for the Meyers 200D. He used to own a Meyers 200D and is extremely familiar with the aircraft. He has been quoted in a number of aircraft magazines concerning his experiments in reducing aircraft sound levels and has reduced the noise level of his own airplane from 94 decibels to 80 decibels, which is lower than a normal conversation.

A super soundproofing package will be offered for the Meyers 200D which can be installed on the production line, thus reducing the manufacturing cost. This soundproofing and an optional stereo system will set the Meyers 200D above the rest of its competitors.

![]()

In the 1950's and 1960's, light plane air-conditioning was unheard of. It was perceived as almost macho to be uncomfortable in small aircraft. Today, creature comfort has risen high on the priority list. Thus, air-conditioning will be standard on the Meyers 200D.

Aviation has become important in the Southern States. Business use of small aircraft is steadily increasing. Fully one-half of the qualified buyers indicated that they would take air-conditioning as an option if it were available. Furthermore, as more pilots and passengers are female than in the past, temperature comfort seems to be even more important. The Meyers 200D should keep one comfortable as well as any expensive luxury automobile.

Kieth Products, the former JB Air (a division of Parker Hannefin) has been selected, principally because of its work on the Sia Marchetti Air Force Trainer contender, to design the air-conditioning systems for the Meyers 200D. The system designed by Kieth had to impose no drag loads, such as the older drop down condensers on some Pipers. This was because any drag could adversely affect the acrobatic handling qualities of the aircraft. Also, the Sia Marchetti has a bubble canopy, similar to the Meyers 200D and the system has demonstrated the ability to handle large air-conditioning requirements caused by this type aircraft.

The installation will consist of a paletized, 28v motor and compressor that can be run with a small GPU without the engine running. Thus the aircraft can be pre-cooled prior to boarding. Also, it is possible to design this type of system such that it can remain on during take-off for additional comfort. And this type system is much more reliable than an engine driven compressor system with the vibration problems, direct engine performance degradation and long lengths of tubing which add weight and tend to leak due to the vibration inherent in aircraft..

![]()

An interior suitable for an expensive sports car will be designed in conjunction with the sound proofing package. Leather will be standard. Attention will be given to air distribution and other creature comforts such as reading lights and make-up mirrors and lighting.

The present seats are not very comfortable and are over 4" thick which takes considerable room out of the interior. The seats are being redesigned using modern orthopedic contours and foams to give excellent long-range comfort while being only 2" thick. This will add 4" of interior leg room. This will enable reading tables and comfortable armrests to be designed and installed.

There is well above average head room already. Some of it will be used for overhead lighting and air distribution so that air conditioning and ventilation outlets will be within easy reach of the occupants. The present heating system is excellent and will be retained.

![]()

Several aircraft artists have been contacted and one or more will be retained to offer new paint schemes which will compliment the Meyers 200D's looks. The standard paint will be a polyurethane type to keep the aircraft looking new longer. New in 2000 is a paint design contest which we are monitoring and several very good designs have already submitted. To see the contest, Click Here.

![]()

There are several minor changes to be accomplished and some, previously approved but not utilized, will be offered. Some of these changes are:

1. The certified Goodyear brakes will be replaced with Cleveland brakes. The Goodyears have not controlled the aircraft well and are expensive to replace. Nearly every Meyers 200D in the field has had this conversion, as has Prop-Jets' Interceptor 400.

2. Different material bushings will be used in the landing gear to reduce the need for frequent replacements.

3. The flap tracks and aileron hinges will have aerodynamic covers constructed to reduce drag.

4. All landing gear doors will be stiffened and rigged properly to avoid pressurizing the wheel wells to reduce drag.

| The original instrument panel on the Meyers 200D is very good and can be easily made even better. In 1967, Aero Commander designed a new panel with three radio racks to the right, the engine instruments in the center, the flight instruments in a pod directly in front of the pilot and annunciation and fuel management panels (see other changes for fuel gauges under Fuel Systems in this Section.). The drawings all exist for these modifications and the design can be incorporated very easily. Even though this was designed in 1967, it will be the most advanced panel in light aviation today. |

|

The original 1967 panel with late 1980's avionics including Century IV AP w FD - Slaved Stormscope - HSI - Slaved RMI - new instruments and electrical wiring. To see several panel design concepts, Click Here. |

![]()

This is the area of aviation where most of the advances have been made in the last 20 years. Likewise, Paul Whetstone, President of Meyers Aircraft, has a wealth of experience in avionics and previously operated avionics companies.

Most of the engineering has already been done for many of the avionics systems pilots want to add as options, and are on Computer Assisted Drawing (CAD) software. Complete CAD drawings of the electrical installation will be provided with every aircraft, something normally not done with light aircraft. This will make it easy for the aircraft to be maintained in the field and for the factory to help troubleshoot and supervise field repairs.

The Meyers 200D is being offered with a factory standard Instrument Flight Rules (IFR) package. Bendix/King avionics are the standard of the industry and were selected for this package. The basic package will consist of:

| KMA-26 Audio panel with marker beacon receiver | (Photo not yet available) |

| KX-155A Nav/Com with Glide Slope receiver |  |

| KX-155A Nav/Com |  |

| KLN-89B GPS receiver w moving map |  |

| KT-71 Transponder w/Blind Encoder |  |

| KI-209A Indicator |  |

| KI-208A Indicator |  |

| Antennas and Splitter | To see some Avionics Design Concepts - Click Here |

Most of the qualified leads for the Meyers 200D have indicated that they want advanced avionics installed by the factory. Options to be offered include an upgrade to a full flight director system, moving map displays, GPS receivers, engine monitoring devices, fuel flow totalizers, Stormscopes, TCAD systems, GPWS systems, AOA systems, intercoms, stereo systems and Nav management systems. There is ample room in the panel for extensive additions. We will be updating the avionics section as options are developed.

Paul M. Whetstone, President

Email pwhetstone@meyersaircraft.com

Meyers Aircraft Company, Copyright © October 1999. All rights reserved. Reproduction in whole or in part of any text, photograph or illustration without written permission from Meyers Aircraft Company is strictly prohibited. Disclaimer: The information presented herein is believed to be accurate and at times expresses the opinions of management. Meyers Aircraft Company assumes no responsibility for its unauthorized use. To report problems or missing links, contact webmaster@meyersaircraft.com